|

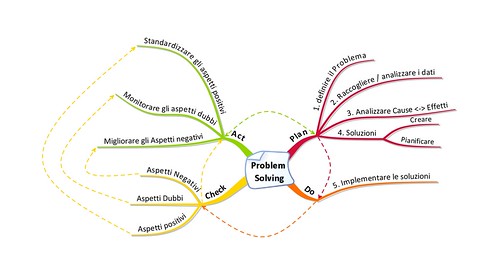

| Problem Solving PDCA, a photo by Luigi Mengato on Flickr. |

PAS55, the British framework for Asset Management, is set to systematise and solidify asset management in the same way that ISO and Six Sigma did for quality, and PRINCE2 did for projects.

PAS55 is built around the Plan Do Check Act (PDCA) loop, as follows

- Plan: Establish the asset management strategy.

- Do: Implement the asset management plan.

- Check: Monitor and measure against the objectives.

- Act: Take actions to improve the asset management performance and system.

PDCA is a great framework for problem solving and for continuous improvement, but my main concern with it is that it can be applied in a very local way. There is nothing in PDCA that talks specifically about Learning from others, nothing in there about sharing Learning with others.

There is no "L" in PDCA.

That's where Knowledge Management can work extremely effectively with PAS55 and other Continuous Improvement systems such as Six Sigma and Quality Circles.

Knowledge Management adds the L.

Knowledge Management works with PAS55 to add the L to PDCA, to create (if you like) a PDCAL loop.

- Plan: Establish the asset management strategy.

- Do: Implement the asset management plan.

- Check: Monitor and measure against the objectives.

- Act: Take actions to improve the asset management performance and system.

- Learn: Share those improvements around the organisation, and learn from improvements elsewhere.

Through PDCAL we not only continuously improve the performance of each individual asset, we share learnings across the assets to improve collective performance at a faster rate, and with greater security, than any one individual asset could do alone.

PDCA is like a cog wheel driving improvement. PDCAL is like a gear train of connected cogs.

No comments:

Post a Comment