Part of the role of KM, particularly in manufacturing and production, is to reduce the cost of non-quality

When I started my Knowledge Management journey in 1992, my job post was entitled "Quality Advisor". I was accountable for the quality of the geoscientific work in the BP Norway office. Because oil wells are drilled (at huge investment) on the basis of geoscientific predictions, the cost of poor quality predictions can be immense.

When I started my Knowledge Management journey in 1992, my job post was entitled "Quality Advisor". I was accountable for the quality of the geoscientific work in the BP Norway office. Because oil wells are drilled (at huge investment) on the basis of geoscientific predictions, the cost of poor quality predictions can be immense.It became quickly clear, in discussions with my manager, than the key to high quality work lay in knowledge; in preserving and transferring the knowledge of the local geology, in building the technical knowledge of the individuals, in importing knowledge from other teams, other offices and parts of the world, and in reviewing and learning from the results of predictions - both successful and unsuccessful.

In other words, we decided to use Knowledge Management to address the cost of non-quality, and my job morphed into Knowledge Manager.

Cost of non-Quality

The Cost of non-Quality is talked about most in terms of product development. Non-quality costs can include- Rework

- Warranty costs

- Service costs

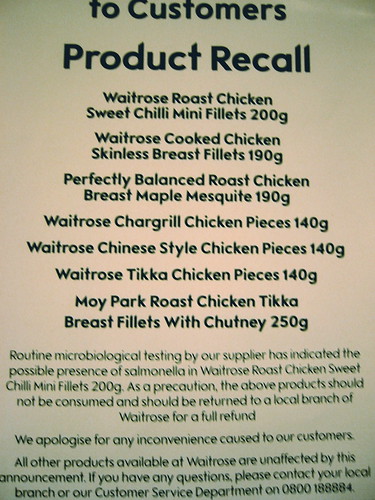

- and, at its worst, Product Recall costs and the associated loss of reputation and sales.

Knowledge management can help address many of these issues, ensuring that a full set of knowledge is acquired at the start of the project (knowledge of the clients real needs, knowledge of the limitations of the technology knowledge from other projects, R&D projects to fill the gaps), and that knowledge is addressed throughout the development project (AARs, or more detailed approaches such as the Toyota A3 process, to ensure all hiccups are fully addressed), and that product design knowledge (not just the planned design, nor even the as-built design, but the rationale and thinking behind the design) is captured and preserved to accelerate service work.

I heard a client last week assert that perhaps half of the non-quality costs could be addressed by good Knowledge Management - KM thus becoming part of the Cost of Quality. So if you already know your Non-Quality costs, then this gives us another way to start to estimate the value of a KM program. And if you don;t already know your non-quality costs, then perhaps you should!

No comments:

Post a Comment